We offer a series of dedicated solutions addressing the specific challenges of a turnaround.

Some activities are executed before shutdown to identify the components that need further maintenance. To speed up the installation activities, some inspections are done during the turnaround. Leak detection is also done after start-up of production to minimize leaks and incidents.

Solutions for your Turnaround

Depending on the specifics of your production installation and the objectives of your turnaround, we apply the following techniques:

- Ultrasonic inspection of steam lines and flare or vent lines, pressure relief valves or internal passing valves

- Ultrasonic leak detection of all opened equipment resulting in a fast and accurate detection that replaces time-consuming and inaccurate soap tests or expensive helium tests

- Wall thickness measurements of pipes or walls

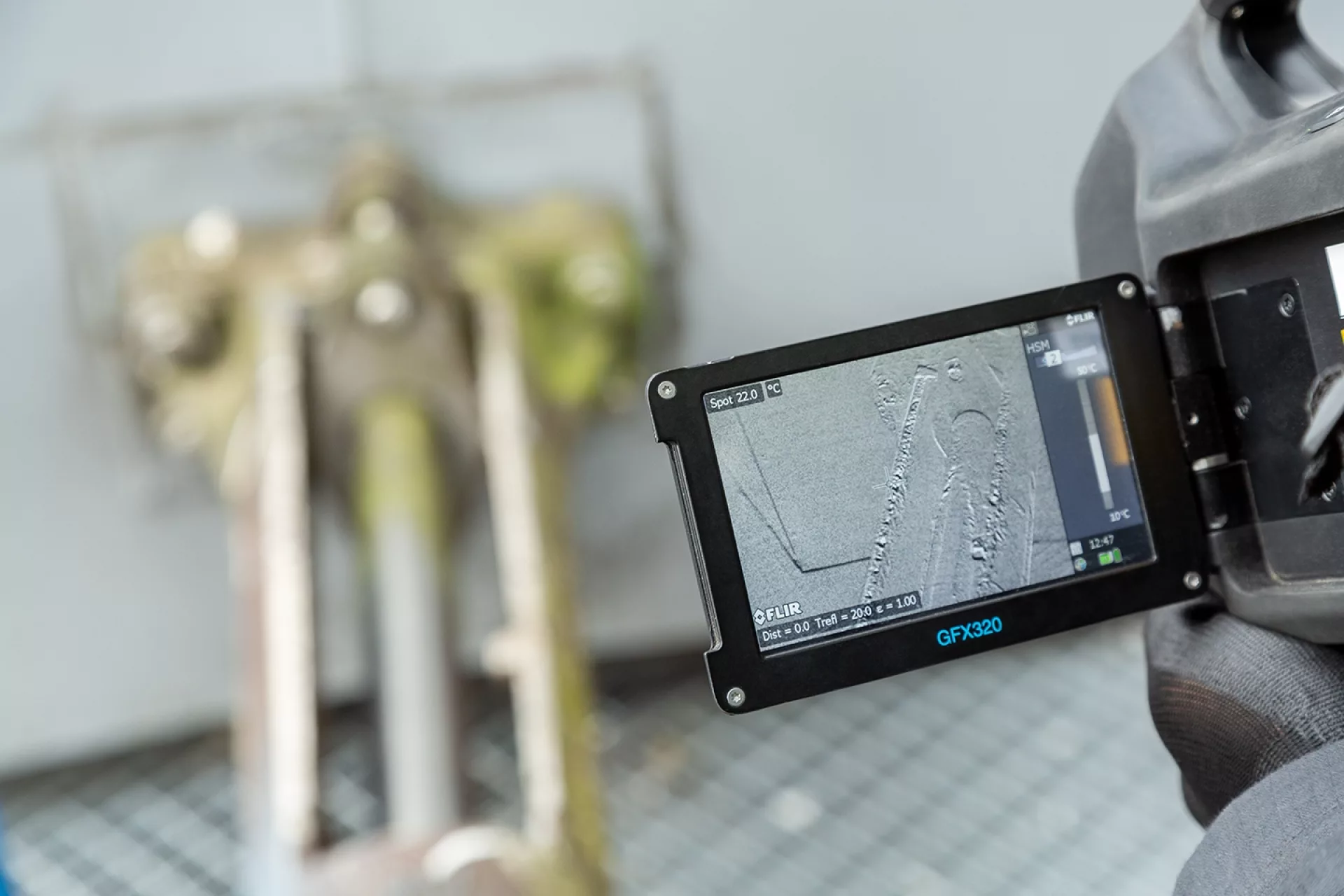

- Thermographic surveys of furnaces, cooling equipment, process components, electrical installations, under insulation components, underground pipelines, etc…

- Leak detection with gas camera or PID/FID leak detection equipment

- Ultrasonic leak detection on N2, compressed air, or vacuum lines

These techniques and services enable the maintenance team to focus their efforts on the key critical components. Effective services guarantee fast and safe production start-ups.

Typical roadmap for turnaround acceleration

OGI screening before Turnaround

Environmental Services reports existing leaks so they can be repaired during the turnaround

Assist start-up with Nitrogen/Hydrogen

Our Industrial Service line can start-up your installation with nitrogen/hydrogen. Afterwards, the Environmental Services team helps find major leaks using ultrasonic measurements before pressurizing with VOC.

Assist start-up with VOC

Due to the higher pressures and temperature differentials, other leaks might still emerge. The Environmental Services team detect these with our OGI cameras.

We are pleased with the professionalism of the team during the start-up of our plant. We were able to quickly repair several small leaks found with ultrasound measurements. When pressurizing the site, your team was present at the right location at the right time. You were able to locate a leak that remained small (within the norms) but that was invisible for us due to the insulation. Our Turnaround team wants to thank you for your pleasant and flexible work attitude. The aftercare is equally impressive. We look forward to continue using your services in the future!

Roger Plettenberg, Sr. Analyst, Stop Coordination PE, SABIC Manufacturing Geleen