Pipeline inspection services

We provide in-line inspection of (non-piggable) pipelines and heaters including quick scans, full assessments, pre-engineering, mechanical works, mechanical and chemical cleaning, gauging, caliper runs, inspection, xyz surveys, reporting and consulting. Especially the field of unpiggable pipelines is our domain. Intero offers a unique range of integrated services to provide the best solution for your most challenging pipelines.

Safe, trusted, certified. Entirely Intero.

Since each pipeline is unique, standard technologies and services do not always suffice. Decades of experience combined with cutting edge technology allows us to find creative solutions for specific challenges, while simultaneously providing customized technical solutions and adaptive field application. High-end engineering enables us to develop custom tools and equipment, while a certified, well trained and seasoned group of field engineers can apply these solutions anywhere in the world.

Our pipeline inspection equipment is based on ultrasonic technology. Our ultrasonic systems are capable of providing high resolution data with the best defect sizing accuracy available. Intero’s high quality ultrasonic data allows you to strongly reduce the number of unnecessary dig ups and repairs, execute more accurate remaining life and fit for service assessments and provides the possibility to stretch repair programs for longer periods.

All of our equipment is well maintained and updated in accordance with the latest industry standards. For our clients, the result is high quality solutions, better data, more reliable inspections and less downtime. We are constantly challenging the boundaries and looking to expand our knowledge and experience.

In addition to our specialized inspection tools, methods and equipment, our newly constructed test, training and technology center in The Netherlands, allows us to keep our own and our client’s staff knowledgeable and well-trained.

Unpiggable? Not anymore!

Test our 35 years of experience pigging the unpiggable.

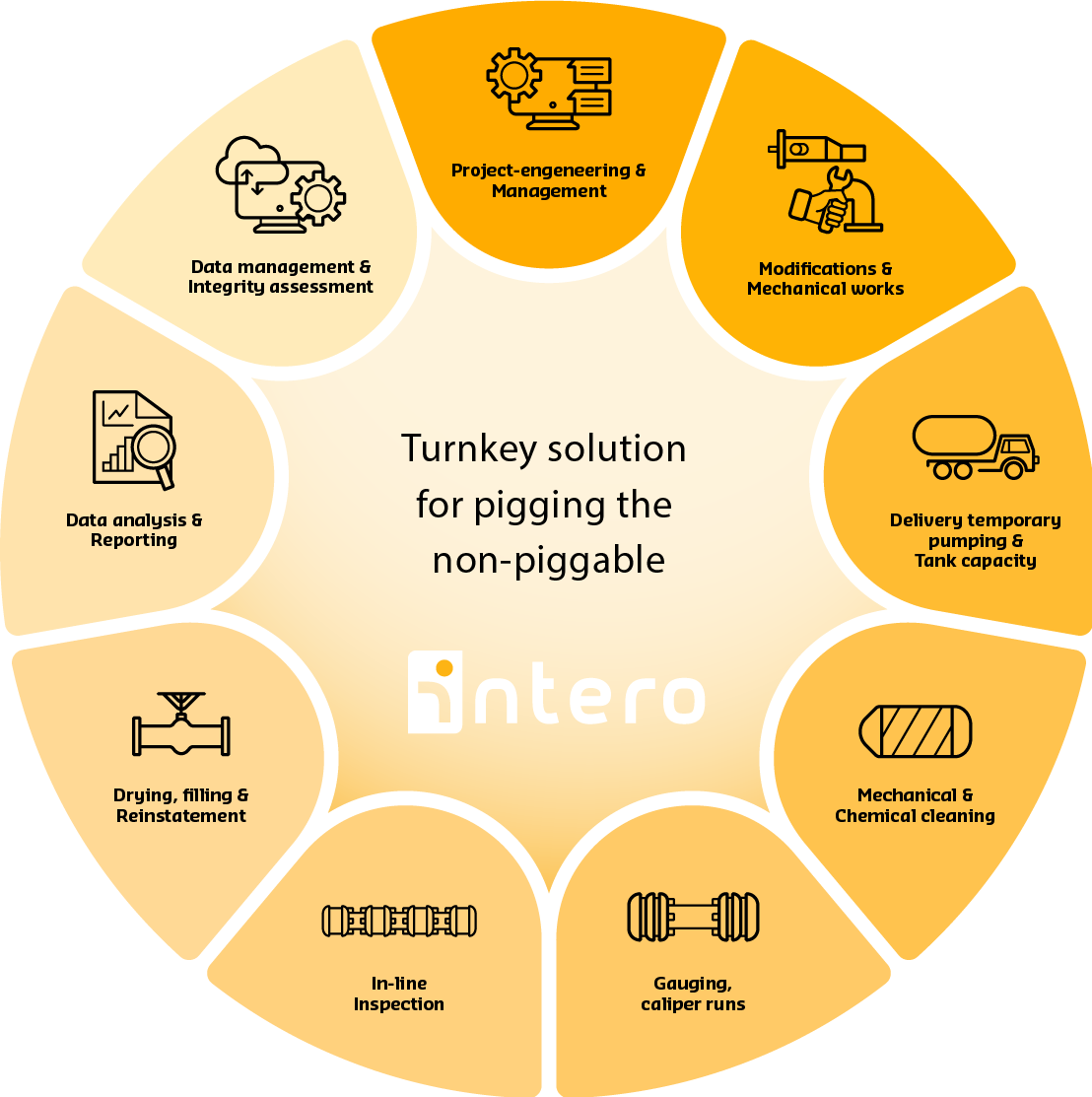

A unique turnkey solution for (non-)piggable pipelines

Intero Integrity Services has the inhouse capabilities to combine all services required to inspect the most complex and challenging pipelines. We provide the engineering required to develop the best approach to make your pipeline piggable. If required we design and manufacture launchers, receivers and spool pieces and deliver this on site for installment. On site we provide the mechanical work and provide pump and tank capacity. The field team can take the necessary D-GPS reference measurements to map the pipeline and enhance any XYZ run accurate. We take care of the mechanical and chemical cleaning, can provide gauging and caliper runs and perform the in-line inspection.

We than commission the line and hand it back to the operation.

On site we provide a site report and the final data analysis and reporting will be delivered a few weeks after. Along with the data we can provide our pipeline data management platform (Pipeline manager) and integrity assessment services (defect and fit for purpose assessment).

This unique, single contractor turnkey approach has many advantages:

- One single contractor, no multiple contractor interfaces to be managed by the client

- Smooth communication

- One crew, minimum amount of resources on-site

- Efficient execution

- Professional project management approach executing entire project

- Minimum downtime