Piggable inline inspection

For the last decennia, pipeline operators have invested in launchers and receivers and numerous related appendages, to make pipelines piggable and regular inspections possible. To supply this market with a competitive ultrasonic inspection tool, Intero Integrity has developed an ultrasonic based inline inspection solution.

Intero's high resolution pipeline inspection solutions:

Better data, more insight, rock solid decisions.

This ILI tool provides a flexible platform to enable inspection of these lines online and while immersed in product, such as liquid. The tool is propelled through the line by the liquid and, due to its enhanced velocity, allows more options for using batches in gas pipelines. To go with the flow.

Our tool combines the advantages of ‘free-swimming’ and ‘cable-operated’ inspection systems and, as a result, has eliminated the disadvantages of both. Furthermore, the system is suitable for passing small radius bends, mitered bends and multiple diameters, and can be bi-directional.

Inspection technology

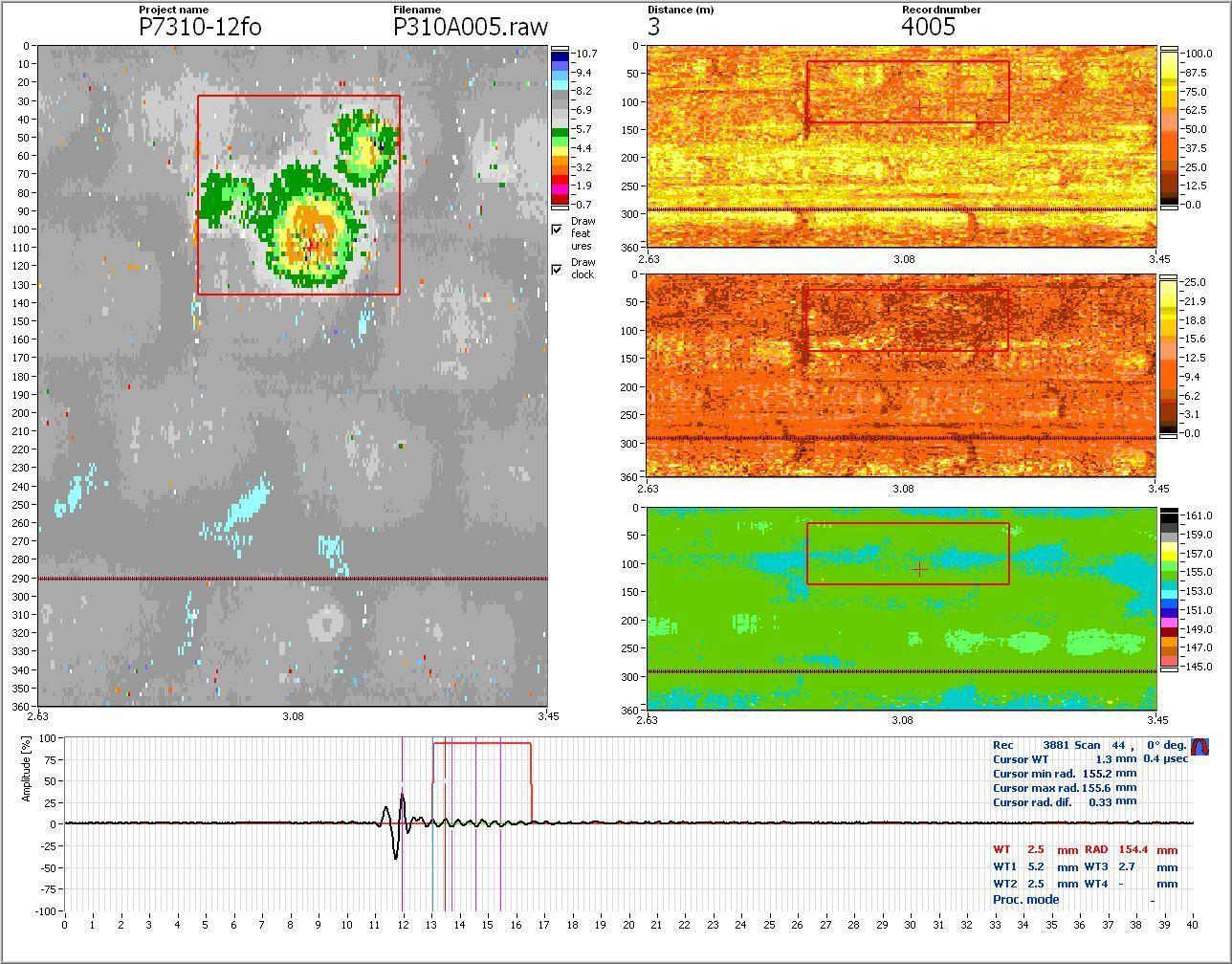

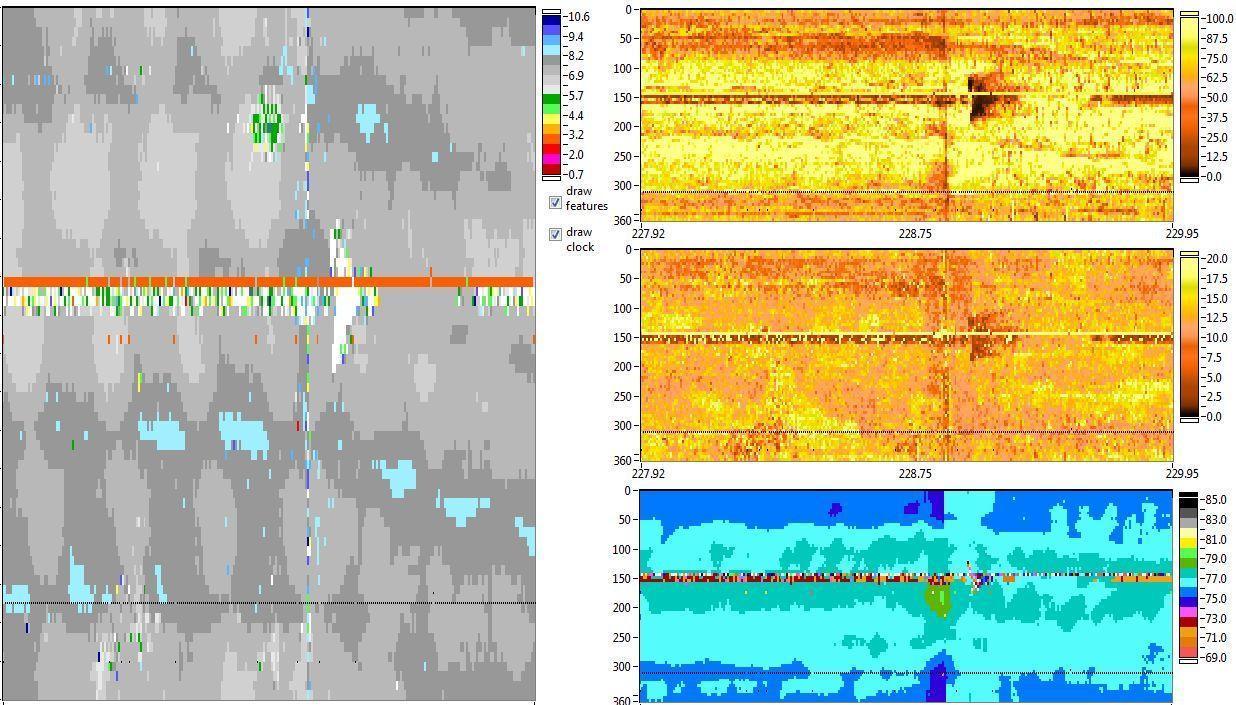

The measurement technique used is ultrasound equal to our Piglet unpiggable inline inspection solutions. The Piglet tool is equipped with a measuring device that uses ultrasound waves for measuring the wall thickness and inner radius of the pipe. One run combines a wall thickness inspection as well as a geometry inspection, no additional caliper runs are required.

The ILI-Piglet system has the ability to:

- Inspect pipeline lengths up to 40 km in one run

- Negotiate an unlimited number of bends

- Travel in two directions (bi-directional)

- Inspect multiple diameters in one run

- Perform a wall thickness, geometry and XYZ survey in one run

- Store data on-board as well as provide all ultrasonic measurements online

- Save raw ultrasonic data for detailed post-processing analysis

Data analysis

Using our in-house developed inspection tool, in combination with our highly qualified personnel and the most sophisticated software, the final report is the deliverable component of a pipeline inspection. The purpose of our data analysis and final report is to accurately inform pipeline owners and operators of their asset’s condition.

Our final reporting service is based on an intelligent data analysis system controlled by our highly trained data analysts. When it comes to reporting, quality and accuracy are essential. All work performed by our data analysts is reviewed and verified by an additional level 2 or level 3 data analyst. In addition, all final reports are independently reviewed and verified by a level 3 data analyst.

During data analysis and final reporting we carry out a defect assessment as standard and offer fitness-for-purpose reporting if required.

We also offer:

- Immediate notification policy – any feature with a depth ≥ 80% or a failure pressure ≤ MAOP must be reported immediately to the client

- Integrity management through PIMS software

- Defect assessment: ASME B31.G, Modified B31.G, RSTRENG, SHELL92, DNV

- Corrosion growth rate analysis – back-to-back or historical