How to start with Leak Detection And Repair to guarantee future success

Are you getting ready for the upcoming EU Methane Regulation or does your company want to start with monitoring fugitive emissions? If performing Leak Detection And Repair is a new requirement for your company, you will most likely have many questions about how to get started.

In this blog post, our Environmental Service Line shares how to set up and prepare your LDAR program to guarantee future success.

Preparation is key

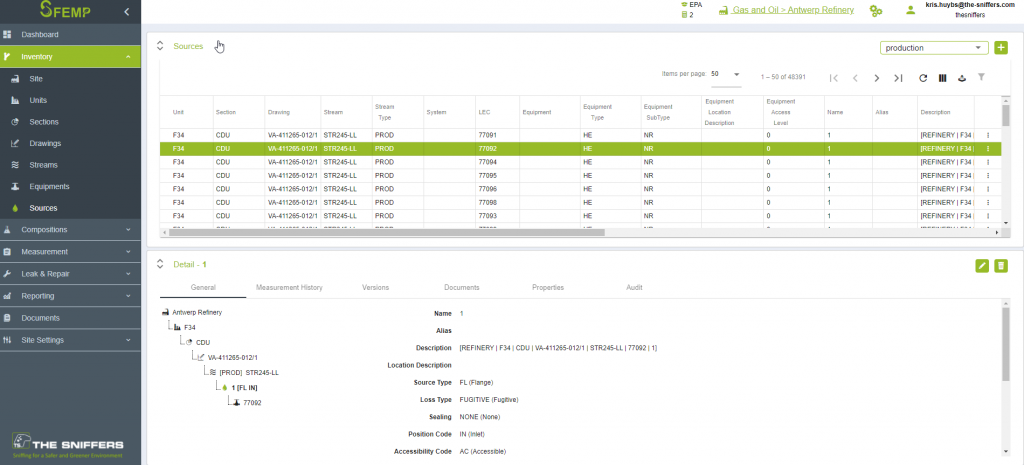

For an LDAR program to be successful, it is essential to have a complete and correct picture of your current emission situation. The baseline of any successful LDAR program is a detailed and complete inventory of all emission sources.

For each of the components in your facilities, all potential types of emissions (fugitive emissions, intended emissions, safety infrastructure-related emissions, venting and flaring, maintenance emissions, etc.) are identified and registered in a proper emission management software application from site-level down to source-level. It is an illusion to believe that managing and structuring all this information manually to then retrieve credible emission figures is feasible.

Apart from the emission types, the stream compositions are also documented. Documenting this allows a correct knowledge of methane, hazardous air pollutants such as benzene, or any other substance.

An inventory can be built using the following input:

- P&IDs

- Flow diagrams (PFD’s)

- Heat material balances

- Safety data sheets

If the P&IDs are of decent quality and they are kept up to date, we build an accurate inventory from the P&IDs. If this is not possible, a source inventory has to be built on-site. Building an inventory is mandatory to reach OGMP Level 4 or the Gold Standard and to comply with the upcoming EU Methane Regulation.

3 types of source inventory

We distinguish 3 different levels of source inventory. The higher the level, the more intelligent the data is and the more capabilities you have to analyze the data.

Level 1: counted database

A counted database includes the total number of equipments per source type (f.e. 10.000 flanges, 500 valves, 20 compressors…). This type of inventory is the minimum requirement to calculate emissions according to EPA Method 21 / EN 15446 / API screening factors for OGI cameras.

However, it is important to note that is difficult to manage changes to this type of inventory and re-counting is necessary, which is a time-consuming effort. From our experience as an environmental service provider, the counted database method is only used by a few clients. The majority of our clients prefer level 2 or level 3 inventories.

Level 2: inventory with minimum source properties

This type of inventory includes unique equipment IDs with minimum inventory parameters such as access level, size, insulation, etc. The equipment IDs are marked on P&IDs. All individual sources are linked to the product stream compositions. Changes can be easily made to this inventory and it is easy to manage.

Level 3: inventory with maximum source properties

The level 3 inventory type is built on level 2 with additional information. Inventory parameters now include access level, size, location, pressure, insulation, equipment IDs of the client in SAP, and so on.

The P&IDs are uploaded to a database and are connected to the sources. A level 3 inventory provides the most data analysis capabilities.

Is there a common goal to reduce emissions?

For LDAR campaigns to be successful, multiple layers of your organization should be involved and have a common mission to reduce emissions. Often, we see that the HSE department is enthusiastic but other departments are not involved. Performing an LDAR campaign goes far beyond reducing emissions.

You save product (gas), you increase the safety on site, your maintenance team will be able to work more efficiently with clear repair orders of found leaks, you comply with regulations, and reach emission targets.

In the below image, we visualize the LDAR strategies in an organization on a strategic level, tactical level, and operational level.

Implement a structural LDAR cycle

Once emission reduction is a goal throughout your organization, it is essential to stick to an LDAR cycle and have a positive attitude toward repairing leaks. The below image illustrates what this cycle can look like.

Performing more measurements does not equal reducing more emissions

Do you think that performing measurements more often will lead to reducing more emissions? This is not necessarily the case. When there is insufficient attention for following up and repairing leaks in a structured way, performing measurements will only result in finding the same leaks over and over again.

We typically see a strong reduction of fugitive emissions in the first years when clients immediately repair the found leaks. When clients perform LDAR yearly, this often results in a more stable situation with lower emission rates since the biggest leaks have already been repaired at the beginning.

Questions about LDAR?

Do you have a question about LDAR? Don’t wait until the EU Methane Regulation enters into force and let’s start defining your LDAR program now.

Our LDAR process and reports meet OGMP 2.0 Level 4 Reporting by default. Moreover, our LDAR program received the ISO 17025 612-TEST accreditation from Belac and 389-TEST accreditation from ISRAC. Reach out to our experts for more information.

40 Years at Intero – A conversation across generations

Handing Out 60 Sheltersuits in Vranje, Serbia