For maximum flexibility, our UT ILI Pipeline Surveyors applies a contact-free ultrasonic measuring head that is able to scan the full surface of the pipe wall. Dual diameter, mitered bends, full-bore unbarred tee pieces, and single entry configurations are well within the capabilities of our system and can be inspected utilizing regular, high, and ultra-high resolutions. Our innovative solutions provide insight in unpiggable pipelines ranging from 3” to 64” and located from subsea offshore to remote areas anywhere in the world.

Unpiggable? If we can't do it, no-one can.

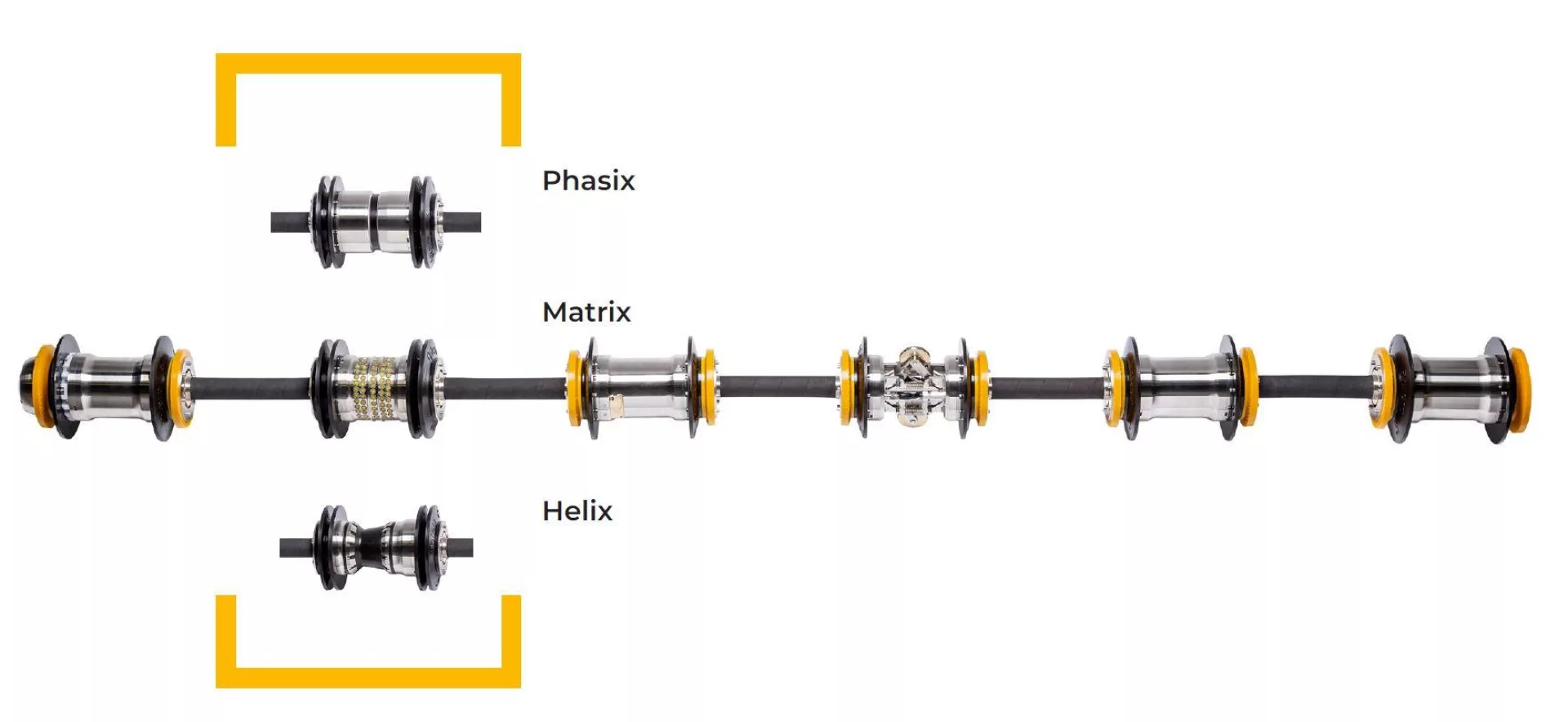

Pipeline Surveyor Family

Intero's Pipeline Surveyors are designed to inspect difficult-to-inspect (DTI) pipelines and can provide real-time data during the inspection. Our state-of-the-art Pipeline Surveyors are adept at examining dual diameter pipelines, maneuvering through mitered bends, assessing full-bore unbarred tee pieces, detecting changes in wall thickness, and evaluating single-entry configurations with unparalleled accuracy.

Introducing the Phasix

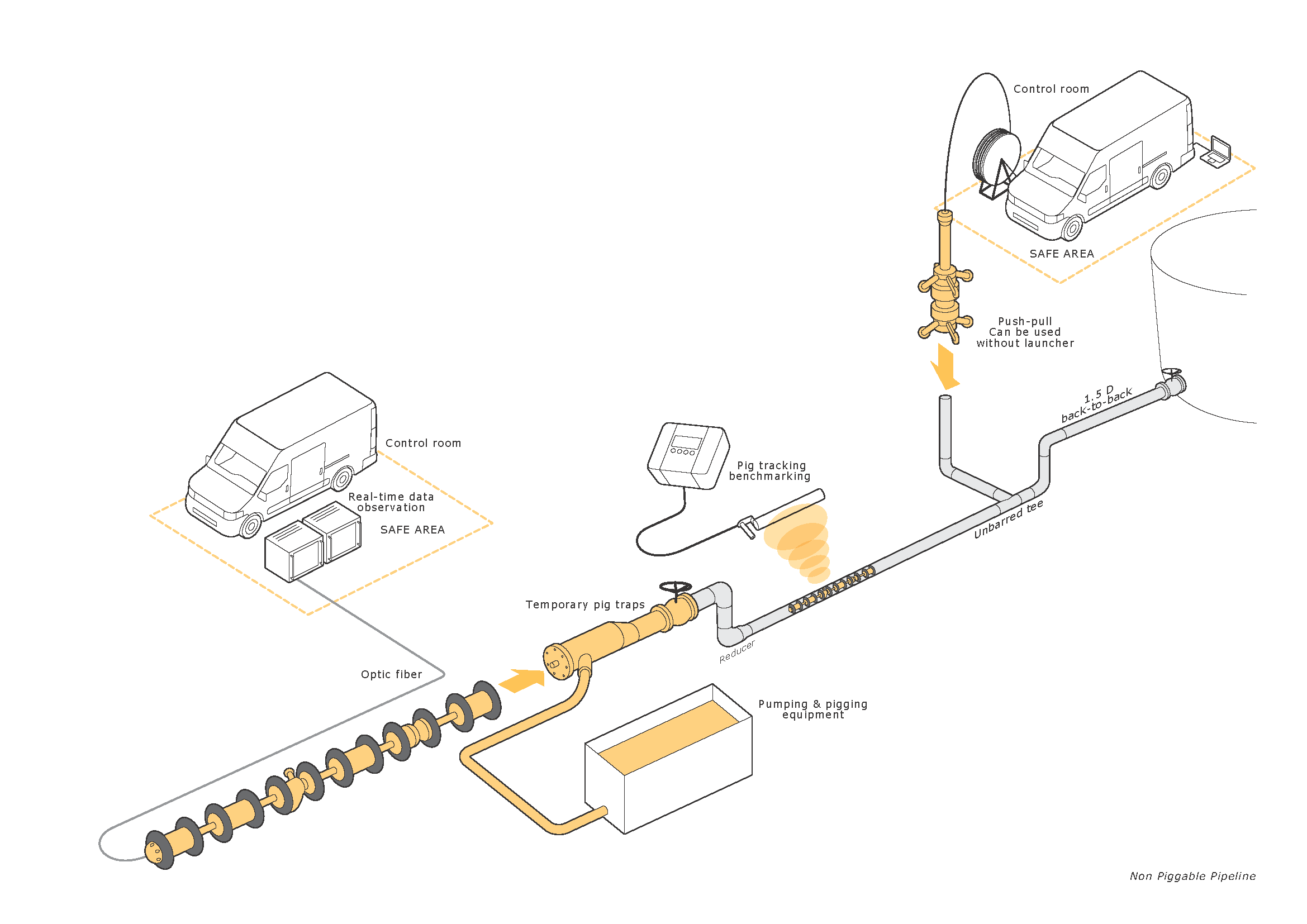

Our unique turnkey approach

The inspection of complex, challenging pipelines require multiple disciplines including engineering, mechanical work, cleaning, inspection, commissioning. To avoid subcontractor interfaces between these disciplines and ensure safe, smooth and efficient project execution, Intero provides a unique single contractor turnkey approach. As a result, our services, including, custom pig design, fabrication and engineering, project management, onsite pumping and pigging, subcontracting, ultrasonic inspection, defect and fit for purpose assessment and pipeline integrity management solutions, can all be provided as one integrated package.

Effective solution

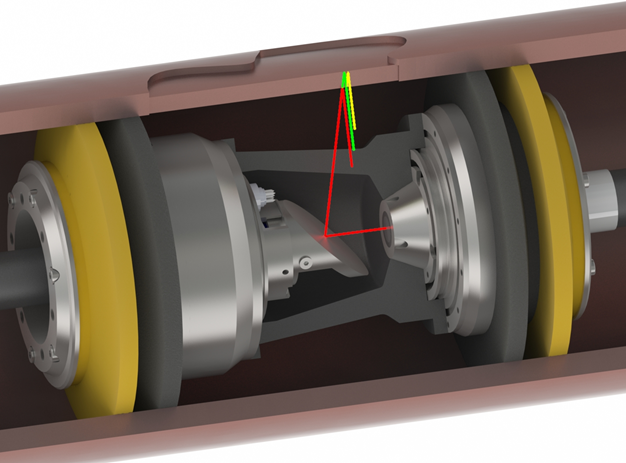

The ultrasonic system is based on direct ultrasonic measurement with time of flight (TOF) measurement so that accurate absolute wall thickness data can be gathered. This allows a full overview of any wall-thickness reductions that may impact the pipeline’s integrity. Simultaneously, the centralized set-up of the UT-head allows measurement of the pipeline’s geometry, detecting any deformation (like ovalities, dents and buckles) easily and accurately. This is critical when third-party damage may be applicable.

An on-board IMU (inertial measurement unit) measures the routing of the pipeline. In combination with D-GPS measurements, this allows spot-on XYZ mapping for integration in Pipeline Management systems, and allowing accurate determination of the location of detected defects based on the inspection.

To allow the best possible interpretation, the system stores the raw ultrasonic A-scan data of each measurement. This enables a detailed analysis of defects, allowing re-evaluation and preventing errors due to algorithm induced analysis. The system can be utilized free-swimming as well as tethered using a hair-thin fiber optic umbilical capable of negotiating the most complex pipelines and limitless number of bends and fixtures while maintaining a real-time connection. This allows for immediate observation of the inspection and short-term feedback on the results. This means immediate decision-making on-site is possible.

For the inspection of short pipe sections (offtake pipes) without the need for temporary pigging and pumping equipment, Intero has developed a hand-fed, push-pull system which can be applied with minimum downtime and yield results instantly.