Intero's Pipeline Surveyors are designed to inspect difficult-to-inspect (DTI) pipelines and can provide real-time data during the inspection. Our state-of-the-art Pipeline Surveyors are adept at examining dual diameter pipelines, maneuvering through mitered bends, assessing full-bore unbarred tee pieces, detecting changes in wall thickness, and evaluating single-entry configurations with unparalleled accuracy.

NEW - Phasix: Revolutionizing Pipeline Inspection!

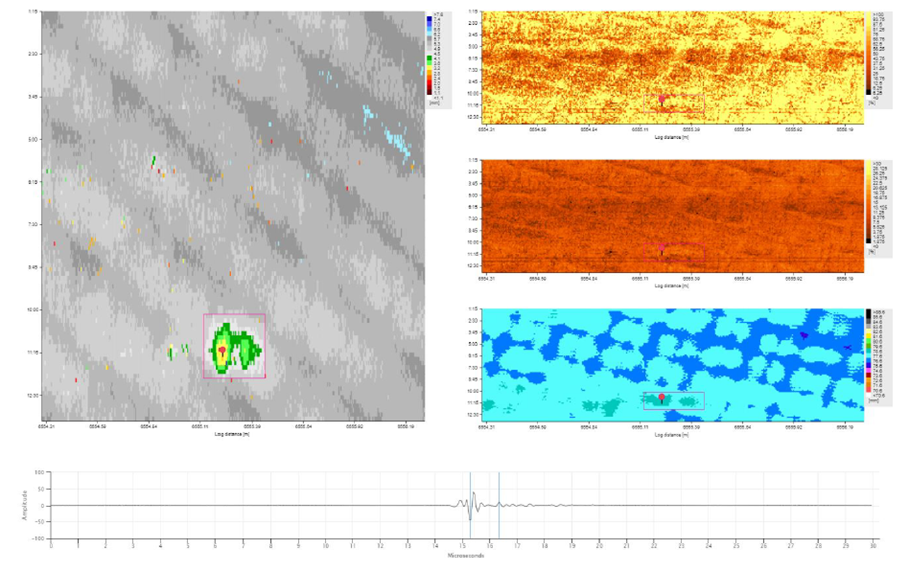

Phasix isn’t just another tool for pipeline inspection. It’s a next-gen ultrasonic powerhouse that scans with precision and speed, thanks to its unique technology. With ultrasonic technology that uses sound in powerful new ways, it’s faster, sharper, and more versatile than ever before.

Introducing the Phasix

Unpiggable? We don't think so.

Equipped with bi-directional capabilities, our inspection tools effortlessly navigate through tight bends of 1.5D or tighter, ensuring thorough examination of your pipeline. Utilizing advanced UT inspection technology, we deliver high-quality, precise integrity data for your pipeline. Supported by our experienced field crews, we offer comprehensive solutions to ensure a safe and successful inspection of even the most challenging pipelines.

- High speed

- Adaptable grid

- Optimizable UT-spot

- Extremely high grid

Reporting

During our inspection with the Pipeline Surveyors we can provide you online and onsite inspection data. The final data analysis and reporting will be delivered in a few weeks after. Along with the data we can provide our pipeline data management platform (PRIMS) and integrity assessment services (defect and fit for purpose assessment).

The Deliverables You Need for Making Informed Pipeline Integrity Decisions