Heater inspection services

Heater Surveyor

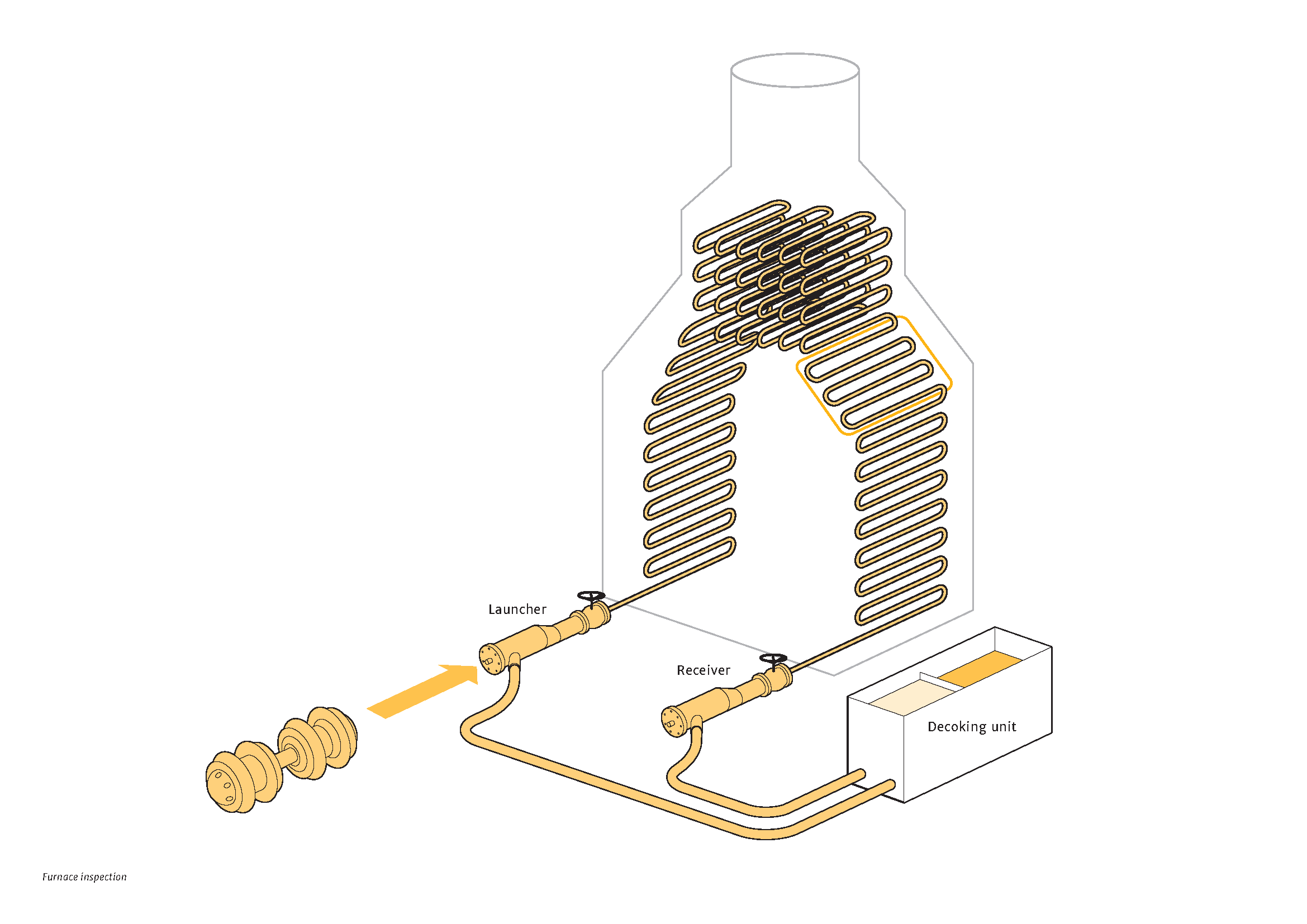

The so-called second generation Heater Surveyor is for the inspection of heater/furnace tubes, whether they are smooth, studded or finned. Intero Integrity Services designed Heater Surveyor is an intelligent free-swimming tool that is capable of inspecting the tubes and bends of the furnace, with a minimum impact on shutdown time.

Prior to a heater inspection it is essential to clean the heater thoroughly to remove all the cokes in order for the ultrasound to penetrate the pipe wall. The proven Intero Decoking Technology (IDT) provides excellent cleaning results. When combined with Heater Surveyor inspection technology, it is possible to guarantee the cleanliness of the furnace tubes.

Integrity of the heater

High quality cleaning and inspection contributes to the integrity of the heater, resulting in minimal shutdown time. Regular cleaning and inspection increases the reliability and continuity of your heater and knowing the remaining wall thickness of the heater tubes can also lengthen their lifecycle and prevent unwanted shutdowns.

Intero heater inspection data.

Accurate, fast, reliable. Entirely Intero.

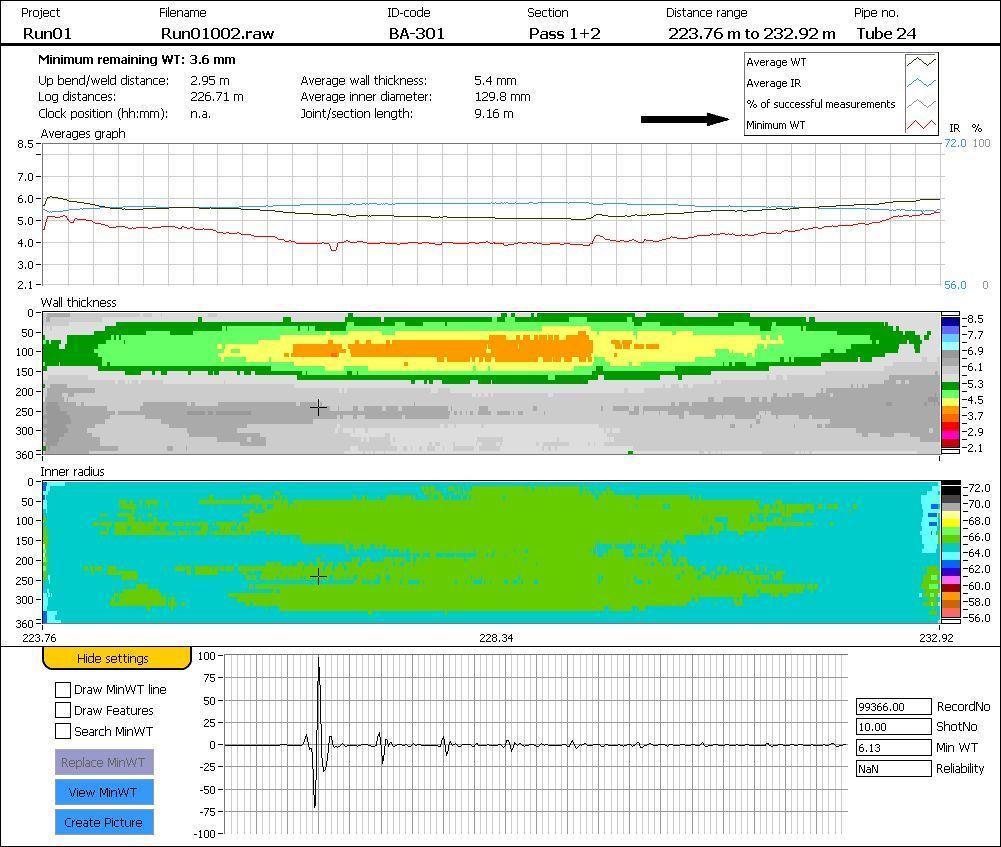

A-scan data

The compact, lightweight, modular design of the Heater Surveyor allows a user-friendly, high performance, ultrasonic inspection of furnace tubes and bends with all ultrasonic measurements stored internally. The storage of the raw A-scan data enables highly accurate and reliable data analysis. The final report is presented within 24 hours after the inspection when the results of the cleaning, if needed, and minimum wall thickness per tube are presented. The report contains a brief overview in graphical and tabular format linked to the heater layout as well as detailed C-scan graphics for each tube.